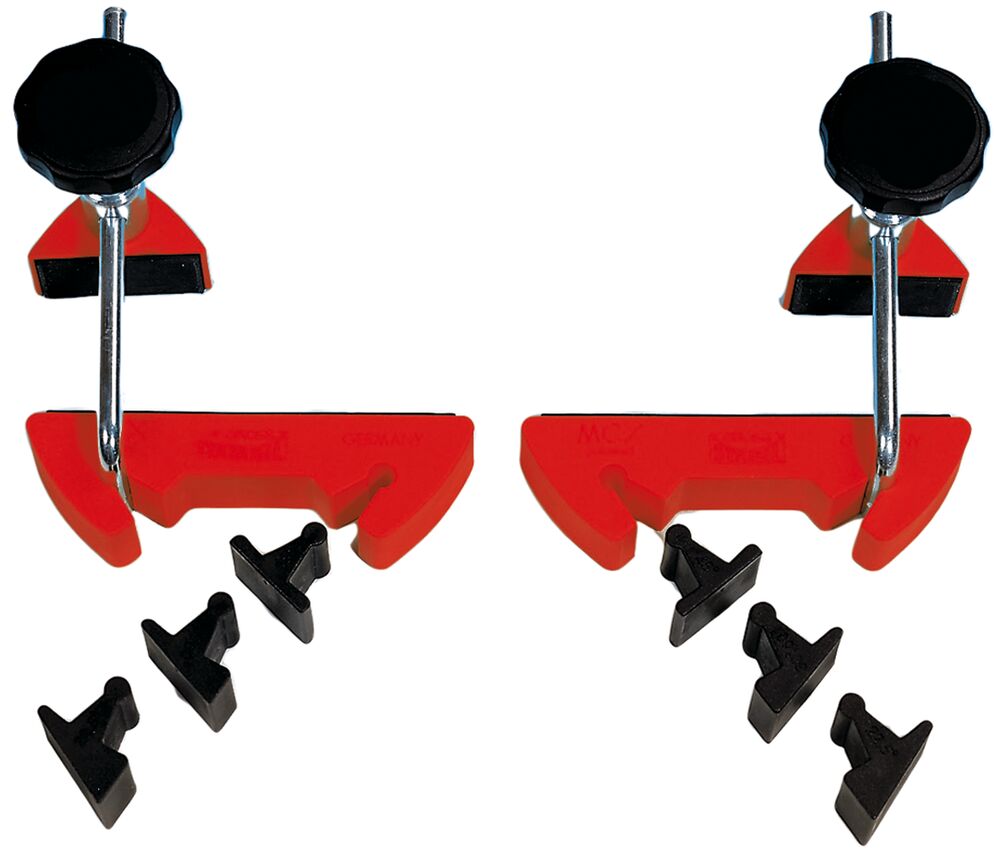

OMEGA‑screw clamp GMZ with tommy bar

| Order number | Opening | Throat depth | Rail | Weight |

| mm | mm | mm | kg | |

|---|---|---|---|---|

| GM20ZK | 200 | 100 | 19,5x9,5 | 0.88 |

| GM25ZK | 250 | 120 | 22x10,5 | 1.25 |

| GM30ZK | 300 | 140 | 25x12 | 1.84 |

| GM50ZK | 500 | 120 | 25x12 | 2.22 |

| GM60ZK | 600 | 120 | 25x12 | 2.42 |

Innovative OMEGA bend

The patented OMEGA bend gives you added safety. It means you lose even less clamping pressure, even when vibrations are present.

Maximum flexibility

The clamp forged from a single piece with moulded pressure plate is hardened, tempered and galvanised, making it highly durable and torsion-resistant. The clamps clamp resiliently and elastically.

Close flat clamping

The OMEGA bend allows you to place the clamp absolutely flat to the surface of the workpiece. This allows clamping right into the corners.

Pressure plate

For enhanced serviceability the pressure plate can be changed with no need for tools. It can be replaced very easily and quickly.

- Interior fittings

- Metal construction

- DIY

- Furniture and joinery works

- Locksmith work

- For clamping resiliently, elastically and powerfully

- It's safe to say that it will give you maximum versatility during clamping

- Clamping tools are not suitable for lifting, pulling or transporting.

- Clamping tools may only be clamped manually without using any auxiliary tools.

- Improper use can cause personal injuries or material damage.

- Never change or modify clamping tools. Only use them in their original condition. Only use original‐spare parts if required.

- Fixed and sliding bracket made of tempered steel, galvanised

- Spindle with trapezoidal thread in rolled steel, burnished

- Toggle made of steel, galvanised

- Pressure plate made of steel, cold pressed, galvanised

- Regular maintenance is necessary - only then can a secure hold be guaranteed (no slipping of the sliding bracket)

- Clean the rails with solvent

- Always keep the rail free of grease, oil or dried glue, waxes and silicone-based release agents

- Clean and oil the spindle regularly

- If the rail is shiny, roughen both narrow sides with emery cloth (100 grain)

- Clean and oil the pressure plate regularly