Clamping element with fixed throat depth TW

| Order number | Bolt | Opening | Throat depth | Rail | Weight |

| mm | mm | mm | mm | kg | |

|---|---|---|---|---|---|

| TW16-20-10-2K | Ø16 | 200 | 100 | 22x8,5 | 0.93 |

| TW16-20-10K | Ø16 | 200 | 100 | 22x8,5 | 0.86 |

| TW16-20-10H | Ø16 | 200 | 100 | 22x8,5 | 1.01 |

| TW28-30-12-2K | Ø28 | 300 | 120 | 28x11 | 1.68 |

| TW28-30-14-2K | Ø28 | 300 | 140 | 28x11 | 1.7 |

| TW28-30-12K | Ø28 | 300 | 120 | 28x11 | 1.62 |

| TW28-30-14K | Ø28 | 300 | 140 | 28x11 | 1.65 |

| TW28-30-12H | Ø28 | 300 | 120 | 28x11 | 2.06 |

| TW28-30-14H | Ø28 | 300 | 140 | 28x11 | 2.08 |

Flexible throat depth

BESSEY TWV clamping elements for welding tables not only have infinitely adjustable throat depth, but are also available in 3 handle variants.

100, 120 mm or 140 mm throat depth

On BESSEY TW clamping elements, you can choose among 3 handle variants and 3 throat-depth variants.

Heavy‐duty, custom design

The TWM28 clamping element has a heat‐resistant special pressure plate with sintered steel insert, which can be pivoted up to 35°. On the TW28GRS gripping arm variant the spindle is located on the outside, which enables – among other things – free access to the work area.

Perfect for railings

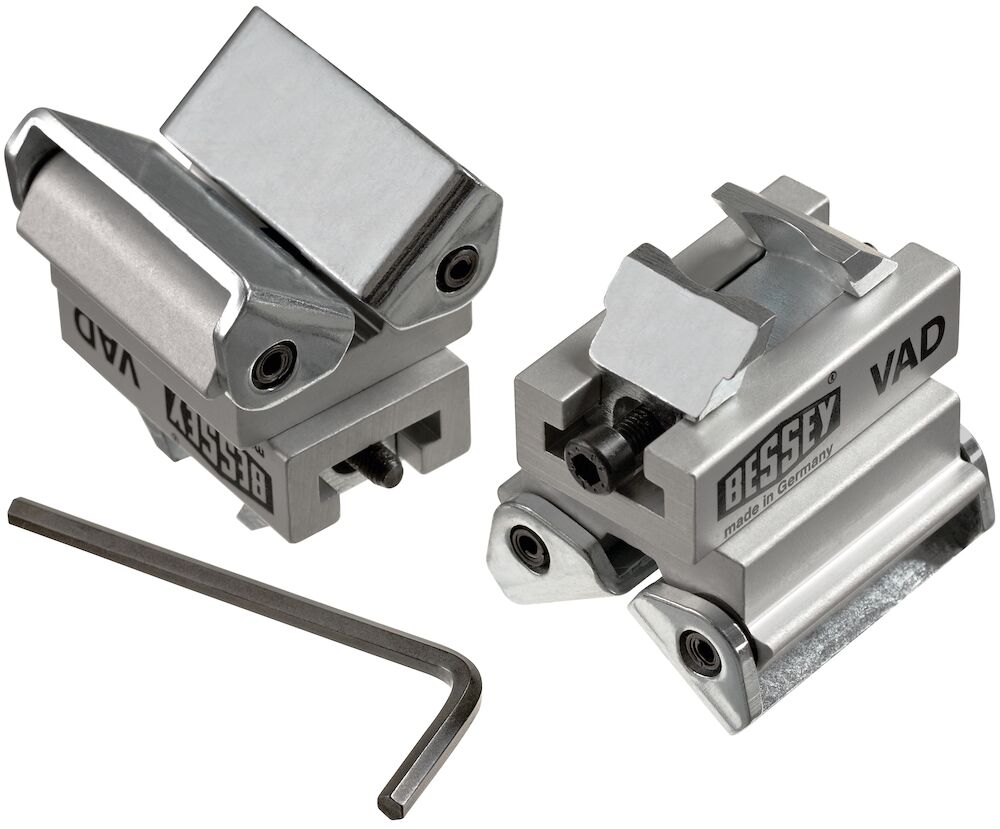

Whether the workpiece is round, oval or square, the TWVAD Vario table clamping attachments are ideally suited

Applying the quick clamp

Thanks to the TWA-STC adapter and the appropriate TWX extension, BESSEY toggle clamps with a horizontal base plate can also be rapidly applied to welding tables.

Diagonal and horizontal clamping

The tilting adaptor TW28AV used in conjunction with the extension TW28X allows angled or horizontal clamping in a range from -52deg. to +52deg.

- Metal construction

- Locksmith work

- Self-welding from the specialists in clamping tools

- Clamping tools are not suitable for lifting, pulling or transporting.

- Clamping tools may only be clamped manually without using any auxiliary tools.

- Improper use can cause personal injuries or material damage.

- Never change or modify clamping tools. Only use them in their original condition. Only use original‐spare parts if required.

- Rail and sliding bracket made of tempered steel, galvanised

- Spindle with trapezoidal thread in tempered, rolled steel, phosphated

- Handle made of 2-component plastic

- Handle made of wood, water-based paint

- Toggle made of steel, galvanised

- Pressure plate made of steel, phosphated

- Connecting elements made of steel, galvanised or phosphated

- Regular maintenance is necessary - only then can a secure hold be guaranteed (no slipping of the sliding bracket)

- Clean the rails with solvent

- Always keep the rail free of grease, oil or dried glue, waxes and silicone-based release agents

- Clean and oil the spindle regularly

- If the rail is shiny, roughen both narrow sides with emery cloth (100 grain)

- Clean and oil the pressure plate regularly (not with lever version)

- Clean and oil the pawl regularly (lever version only)