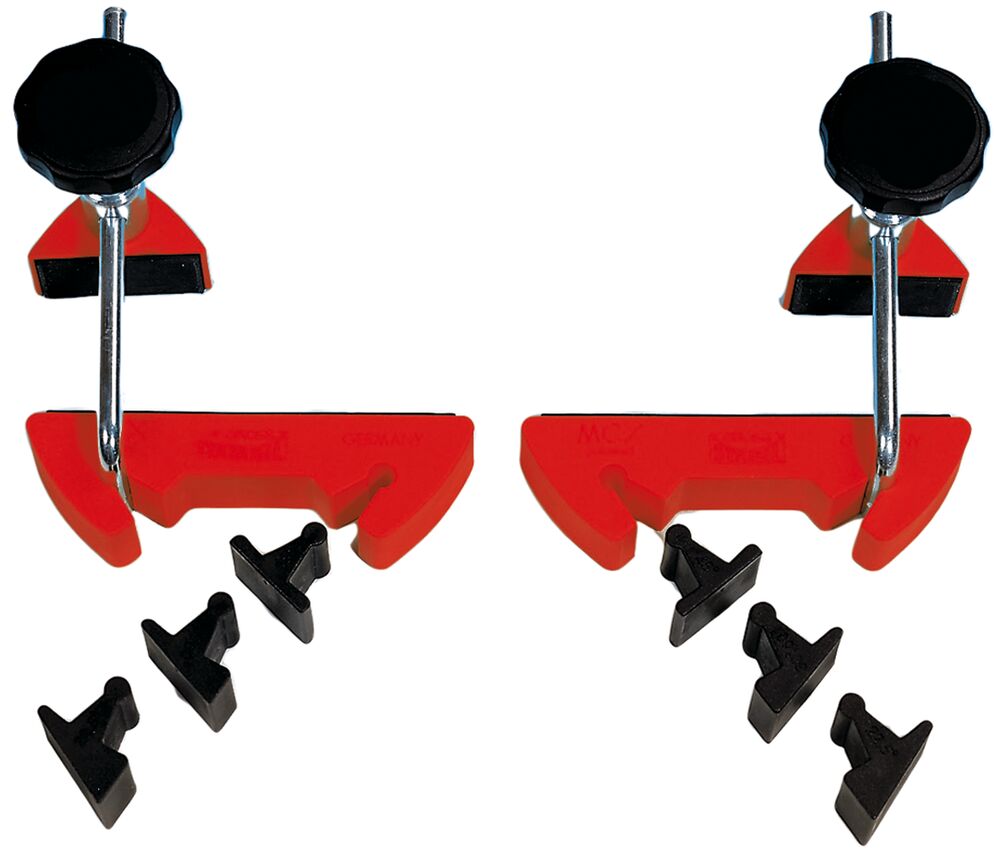

Original BESSEY malleable cast iron screw clamp TG with 2‑component plastic handle

| Order number | Opening | Throat depth | Rail | Weight |

| mm | mm | mm | kg | |

|---|---|---|---|---|

| TG10-2K | 100 | 50 | 15x5 | 0.26 |

| TG12-2K | 120 | 60 | 20x5 | 0.42 |

| TG16-2K | 160 | 80 | 25x6 | 0.66 |

| TG20B8-2K | 200 | 80 | 25x6 | 0.77 |

| TG25B8-2K | 250 | 80 | 25x6 | 0.82 |

| TG30B8-2K | 300 | 80 | 25x6 | 0.87 |

| TG40B8-2K | 400 | 80 | 25x6 | 0.97 |

| TG20-2K | 200 | 100 | 27x7 | 1.06 |

| TG25S10-2K | 250 | 100 | 27x7 | 1.14 |

| TG30S10-2K | 300 | 100 | 27x7 | 1.18 |

| TG40S10-2K | 400 | 100 | 27x7 | 1.33 |

| TG50S10-2K | 500 | 100 | 27x7 | 1.46 |

| TG25-2K | 250 | 120 | 29x9 | 1.54 |

| TG30S12-2K | 300 | 120 | 29x9 | 1.62 |

| TG40S12-2K | 400 | 120 | 29x9 | 1.78 |

| TG50S12-2K | 500 | 120 | 29x9 | 1.98 |

| TG60S12-2K | 600 | 120 | 29x9 | 2.13 |

| TG80S12-2K | 800 | 120 | 29x9 | 2.46 |

| TG100S12-2K | 1000 | 120 | 29x9 | 2.82 |

| TG30-2K | 300 | 140 | 32x10 | 2.19 |

| TG40S14-2K | 400 | 140 | 32x10 | 2.4 |

| TG50S14-2K | 500 | 140 | 32x10 | 2.62 |

| TG60S14-2K | 600 | 140 | 32x10 | 2.84 |

| TG80S14-2K | 800 | 140 | 32x10 | 3.29 |

| TG100S14-2K | 1000 | 140 | 32x10 | 3.7 |

| TG40-2K | 400 | 175 | 32x10 | 2.7 |

| TG50S17-2K | 500 | 175 | 32x10 | 2.9 |

| TG60S17-2K | 600 | 175 | 32x10 | 3.16 |

| TG80S17-2K | 800 | 175 | 32x10 | 3.5 |

| TG100S17-2K | 1000 | 175 | 32x10 | 4 |

Integrated BESSEY anti-slip system

Maximum safety is available with the integrated BESSEY anti-slip system, when clamping with a throat depth of 80 mm or more. A set screw that is molded into the sliding arm interlocks with the serration on the rail. This effectively prevents the clamp from dislodging or slipping away.

Reinforced malleable iron clamps

Both the upper and lower sections are produced from high-quality malleable iron and reinforced by shafts. The powder coating protects against corrosion and the characteristic shaft profile works as a reliable reinforcement against torsion forces.

High‐quality profiled rail

The BESSEY profiled rail from our own drawing plant has been especially optimised for clamps. The serration on six faces additionally prevents the clamp from slipping.

Pressure plate

For enhanced serviceability the pressure plate can be changed with no need for tools. It can be replaced very easily and quickly.

- Interior fittings

- Shell construction

- DIY

- Furniture and joinery works

- Kitchen construction and shop fitting

- Carpentry and woodwork

- Powerful and rigid clamping

- Clamping tools are not suitable for lifting, pulling or transporting.

- Clamping tools may only be clamped manually without using any auxiliary tools.

- Improper use can cause personal injuries or material damage.

- Never change or modify clamping tools. Only use them in their original condition. Only use original‐spare parts if required.

- Upper and lower section made of reinforced malleable cast iron, powder-coated

- Hollow profile rail made of steel, cold-drawn, galvanised

- Spindle with trapezoidal thread in rolled steel, burnished

- Handle made of 2-component plastic

- Pressure plate made of steel, cold pressed, galvanised

- Protective caps made of plastic

- Regular maintenance is necessary - only then can a secure hold be guaranteed (no slipping of the sliding bracket)

- Clean the rails with solvent

- Always keep the rail free of grease, oil or dried glue, waxes and silicone-based release agents

- Clean the fluting on the rails with a steel brush

- Clean and oil the spindle regularly

- If the lower part slips, turn the grub screw a 1/4 turn further (TG, KRE, KREV only)

- Clean and oil the pressure plate regularly