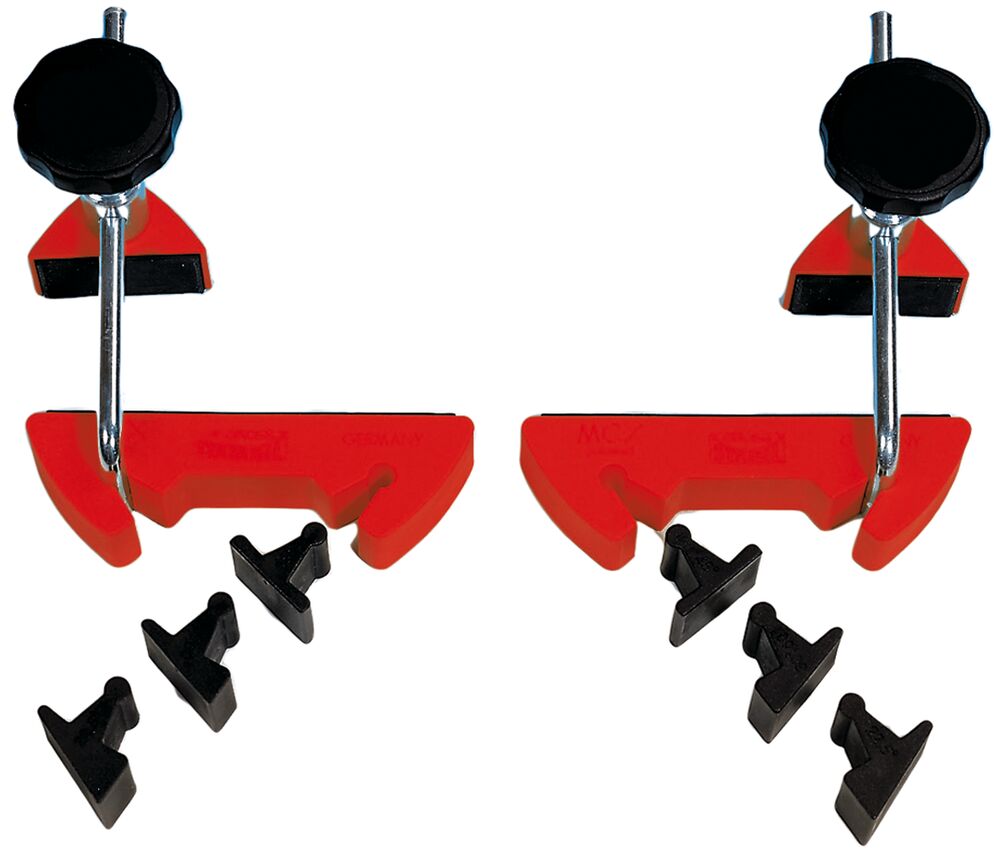

Malleable cast iron screw clamp TPN with tried‐and‐true wooden handle

| Order number | Opening | Throat depth | Rail | Weight |

| mm | mm | mm | kg | |

|---|---|---|---|---|

| TPN10BE | 100 | 50 | 15x5 | 0.26 |

| TPN15B5BE | 150 | 50 | 15x5 | 0.29 |

| TPN20B5BE | 200 | 50 | 15x5 | 0.31 |

| TPN12BE | 120 | 60 | 20x5 | 0.4 |

| TPN20B6BE | 200 | 60 | 20x5 | 0.45 |

| TPN16BE | 160 | 80 | 25x6 | 0.73 |

| TPN20B8BE | 200 | 80 | 25x6 | 0.77 |

| TPN25B8BE | 250 | 80 | 25x6 | 0.82 |

| TPN30B8BE | 300 | 80 | 25x6 | 0.87 |

| TPN20BE | 200 | 100 | 27x7 | 1.16 |

| TPN25S10BE | 250 | 100 | 27x7 | 1.23 |

| TPN30S10BE | 300 | 100 | 27x7 | 1.29 |

| TPN40S10BE | 400 | 100 | 27x7 | 1.41 |

| TPN25BE | 250 | 120 | 29x9 | 1.49 |

| TPN30S12BE | 300 | 120 | 29x9 | 1.58 |

| TPN40S12BE | 400 | 120 | 29x9 | 1.75 |

| TPN50S12BE | 500 | 120 | 29x9 | 1.92 |

| TPN60S12BE | 600 | 120 | 29x9 | 2.07 |

| TPN80S12BE | 800 | 120 | 29x9 | 2.45 |

| TP100S12BE | 1000 | 120 | 29x9 | 2.78 |

| TP125S12BE | 1250 | 120 | 29x9 | 3.2 |

| TP150S12BE | 1500 | 120 | 29x9 | 3.66 |

| TPN30BE | 300 | 140 | 32x10 | 2.03 |

| TPN40S14BE | 400 | 140 | 32x10 | 2.3 |

| TPN50S14BE | 500 | 140 | 32x10 | 2.48 |

| TPN60S14BE | 600 | 140 | 32x10 | 2.66 |

| TPN80S14BE | 800 | 140 | 32x10 | 3.12 |

| TP100S14BE | 1000 | 140 | 32x10 | 3.59 |

| TP150S14BE | 1500 | 140 | 32x10 | 4.68 |

| TP200S14BE | 2000 | 140 | 32x10 | 5.74 |

| TPN40BE | 400 | 175 | 32x10 | 2.58 |

| TPN60S17BE | 600 | 175 | 32x10 | 3.02 |

| TPN80S17BE | 800 | 175 | 32x10 | 3.44 |

| TP100S17BE | 1000 | 175 | 32x10 | 3.85 |

- Interior fittings

- Shell construction

- DIY

- Furniture and joinery works

- Kitchen construction and shop fitting

- Carpentry and woodwork

- Powerful and rigid clamping

- Clamping tools are not suitable for lifting, pulling or transporting.

- Clamping tools may only be clamped manually without using any auxiliary tools.

- Improper use can cause personal injuries or material damage.

- Never change or modify clamping tools. Only use them in their original condition. Only use original‐spare parts if required.

- Upper and lower section made of reinforced malleable cast iron, powder-coated

- Hollow profile rail made of steel, cold-drawn, galvanised

- Spindle with trapezoidal thread in rolled steel, burnished

- Handle made of wood, water-based paint

- Pressure plate made of steel, cold pressed, galvanised

- Protective caps made of plastic

- Regular maintenance is necessary - only then can a secure hold be guaranteed (no slipping of the sliding bracket)

- Clean the rails with solvent

- Always keep the rail free of grease, oil or dried glue, waxes and silicone-based release agents

- Clean the fluting on the rails with a steel brush

- Clean and oil the spindle regularly

- If the lower part slips, turn the grub screw a 1/4 turn further (TG, KRE, KREV only)

- Clean and oil the pressure plate regularly